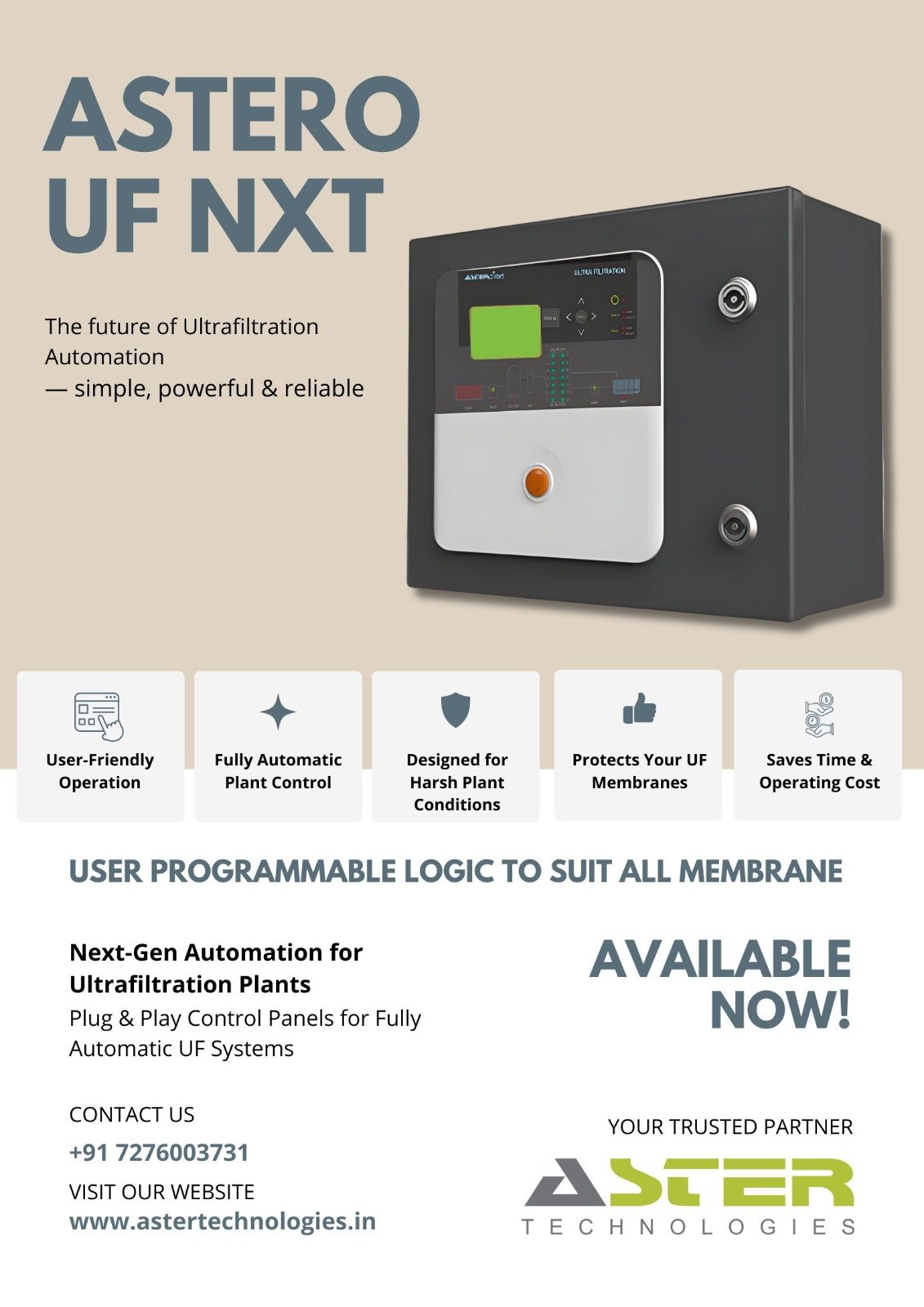

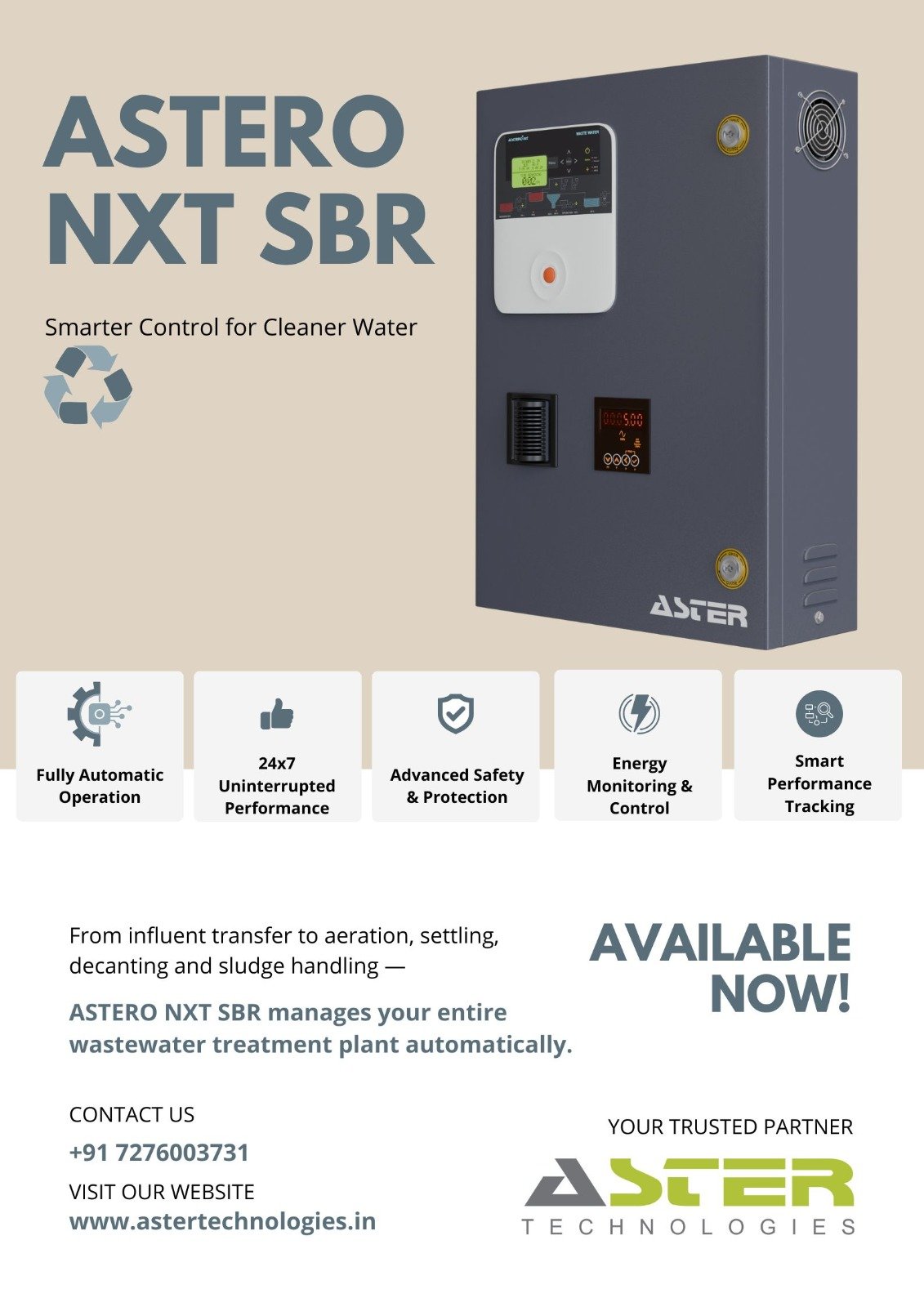

UF NG Panel

Compact Micro-processor based Plug & Play control panels with plant operation programmed and all safeties inbuilt. This panel along with the required level and pressure switch help in making the entire plant completely automatic.

Key Features

Certificates

Key Features

- In-built switch gears for Feed & Backwash pump with required motor protection

- Connections suitable for solenoid as well as motorized valve

- Quick Access to Critical Settings

- Logical START/STOP with Single Key

- Different Colored Backlit to Show Plant Status

- Single Line Mimic Diagram with 13 LED’s for I/O Indication

- 16X2 Alphanumeric Display with Color Changing Features

- Bluetooth Connectivity Plant Status will be reflected on Smartphone

- Can Pair with Android Device for Data Monitoring and Control

- Same Cutout Size with NUT and STUD

- Notification for Filter Backwash and Plant Service Due

- Time Lock Facility

- FUSE Failure Indication

- Larger Power Terminals (6 Sq. mm) for Easy Wiring

- Removable Terminals for Input

- Automatically Flushes the Membrane during Starting, Stopping & after a Set Interval

- Takes Care of required Motor Protection such as Overload, Single Phasing, Dry Running

- Auto/ Manual Facility (even in MANUAL Mode Motor Protection doesn’t get bypassed)

- Equipped to Suit Auto-Multiport Valve in Pretreatment

- Inbuilt Protection Against Over and Under Voltage

Certificates

Key Features

Specifications

Download Brochure

Key Features

- Multiple LED MIMIC DIAGRAM for ease of understanding.

- In built switch gears for Feed & backwash pump with required MOTOR PROTECTION.

- CONNECTIONS SUITABLE FOR SOLENOID AS WELL AS MOTORIZED VALVE.

- SEPARATE OUTPUTS for dosing pumps during Chemical enhanced backwash.

- PROVISION FOR CHLORINE DOSING DURING SERVICE & FORWARD FLUSH.

- ALL STEP TIMINGS ARE SETTABLE AT SITE.

- Set-able Pump on & Pump off delays to AVOID WATER HAMMERING.

- PREPROGRAMMED LOGIC SUITABLE FOR ALL TYPE OF MEMBRANES.

- Facility to HOLD/SKIP/STOP any step.

- USER SETTABLE FREQUENCY for CEB & Backwash cycles.

- In built facility for AIR SCOURING, DRAIN OUT.

- IN BUILT SAFETY against over pressurizing of membrane due to valve malfunction.

- In built memory REMEMBER TIME ELAPSED upon power failure & resumes operation from that point.

Specifications

- Panel Configuration : UF NG

- Overall Size : 345(H) x 255(V) x 130(D)

- Cutout Size : 305(H) x 222(V)

- Display : 16 X 2 alphanumeric display

- Input : RWT Level, TWT Level High Pressure, Dosing Tank Level, TWT Low Level

- Output : RW Pump, Backwash Pump, 2 Doser

- Output (Valves) : 4

* All dimensions are in mm

H- horizontal, V- Vertical

Download Brochure