Astero NXT Wastewater

An excellent alternative for conventional electrical panels. As it has all the switchgear(MCB, Contactor etc) inbuilt with required safeties & plant operation preprogrammed. These panels along with the required level switches help in making the entire plant completely automatic. Ideally suitable for small & medium sized plants as every switchgear has a standby with automatic changeover. This ensures plant functionality round the clock.

Key Features

Certificates

Key Features

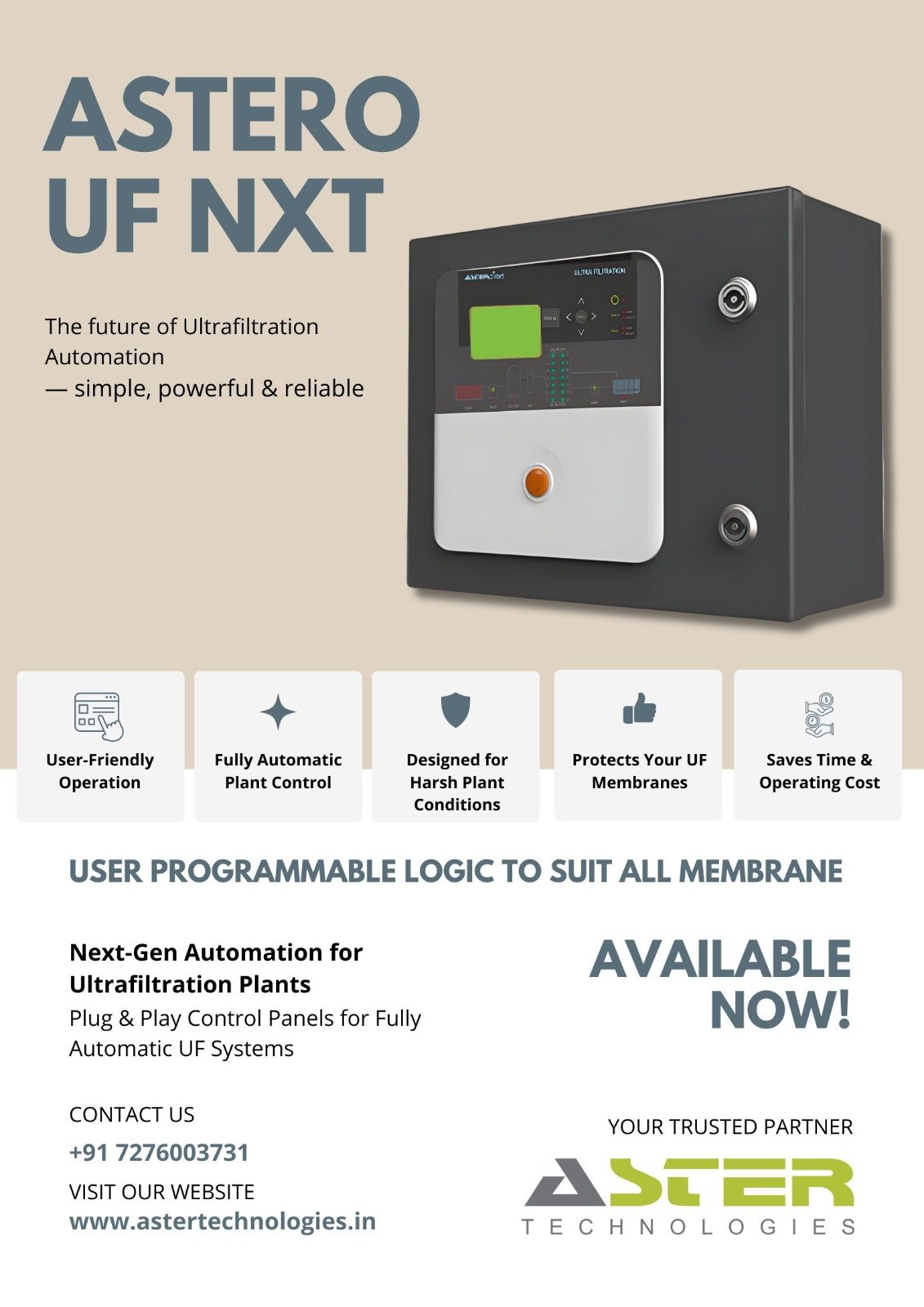

- In-built switch gears for Feed & Backwash pump with required motor protection

- Connections suitable for solenoid as well as motorized valve

- Quick Access to Critical Settings

- Logical START/STOP with Single Key

- Different Colored Backlit to Show Plant Status

- Single Line Mimic Diagram with 13 LED’s for I/O Indication

- 16X2 Alphanumeric Display with Color Changing Features

- Bluetooth Connectivity Plant Status will be reflected on Smartphone

- Can Pair with Android Device for Data Monitoring and Control

- Same Cutout Size with NUT and STUD

- Notification for Filter Backwash and Plant Service Due

- Time Lock Facility

- FUSE Failure Indication

- Larger Power Terminals (6 Sq. mm) for Easy Wiring

- Removable Terminals for Input

- Automatically Flushes the Membrane during Starting, Stopping & after a Set Interval

- Takes Care of required Motor Protection such as Overload, Single Phasing, Dry Running

- Auto/ Manual Facility (even in MANUAL Mode Motor Protection doesn’t get bypassed)

- Equipped to Suit Auto-Multiport Valve in Pretreatment

- Inbuilt Protection Against Over and Under Voltage

Certificates

Key Features

Specifications

Download Brochure

Key Features

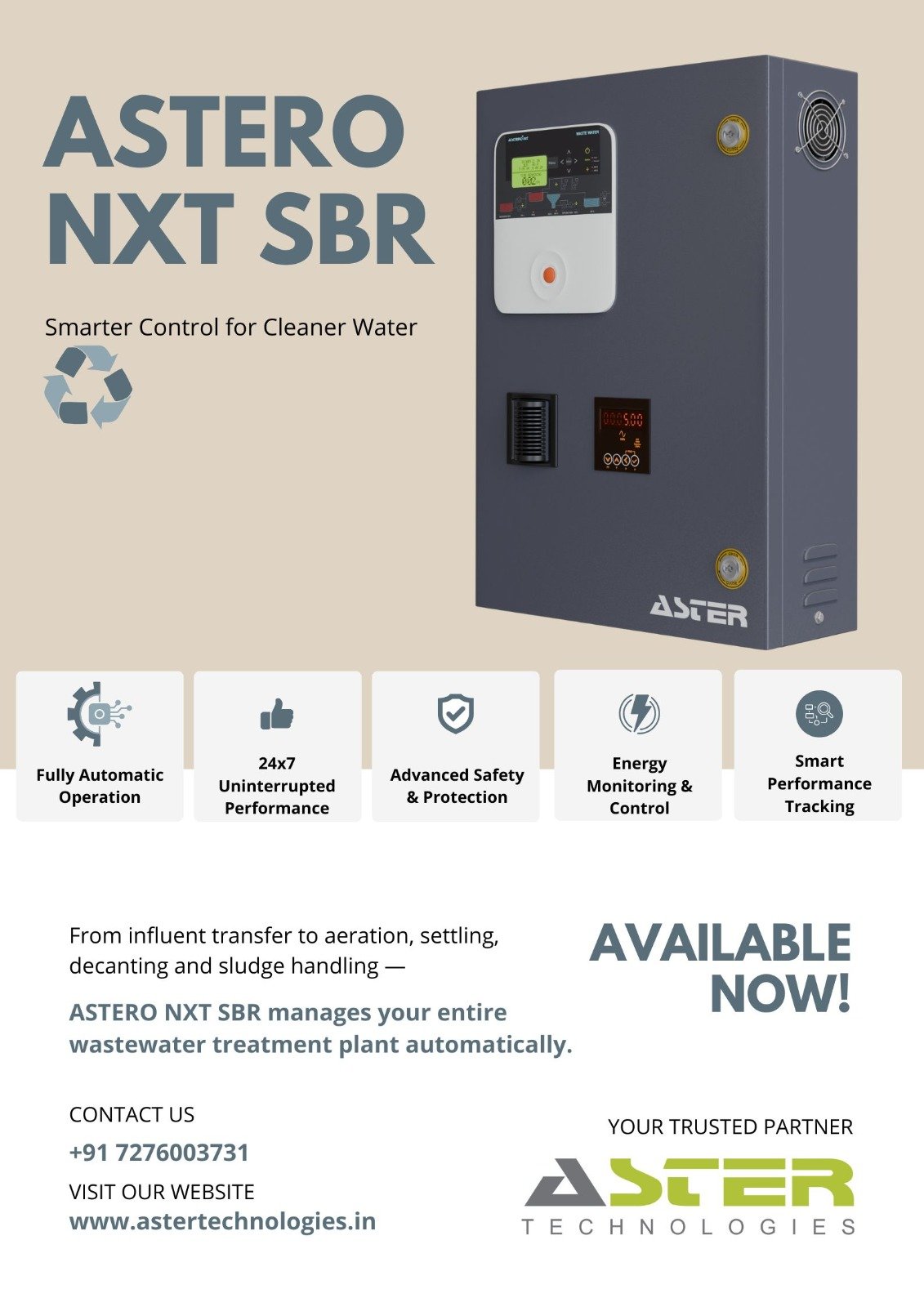

- DUST & VERMIN PROOF ENCLOSURE

- COMPLETE INFLUENT (EFFLUENT/SEWAGE) TREATMENT LOGIC programmed

- ALL PUMPS 1 WORKING + 1 STANDBY auto changeover (Time or Fault based)

- MIMIC DIAGRAM with 13 LEDs for I/O indication

- 20X4 GRAPHIC LCD DISPLAY with keypad for programming

- AUTOMATICALLY DRAINS the SLUDGE after a set period

- SPARE PUMP CAN BE USED AS AGITATOR/SCREW PUMP/FILTERPRESS FEED PUMP etc

- Takes care of required MOTOR PROTECTION such as overload/single phasing/dry running

- SEMI AUTO/AUTO/MANUAL FACILITY (motor protection never get bypassed irrespective of operation mode)

- IN BUILT FLOW RATE INDICATOR WITH TOTALISER

- IN BUILT OPERATION HOUR COUNTER for individual pumps

- IN BUILT TIME OUT facility, panel itself can work as recovery agent

- IN BUILT HOOTER

- COMMUNICATION PORT READY

- PASSWORD PROTECTED settings

- IN BUILT EXHAUST FAN & LOUVERS FOR COOLING

- QUICK ACCESS TO CRITICAL SETTING

Specifications

- Overall Size : 700 (H) x 400 (V) x 25 (D) mm

- Display : 20 X 4 graphic display

- Mounting : Wall/ Skid Mount

- Influent Transfer Pump (1W + 1S) : 5 hp 3Φ (Time Based Changeover)

- Air Blower (1W + 1S) : 10 hp 3Φ (Time Based Changeover)

- Filter Feed Pump (1W + 1S) : 5 hp 3Φ (Time Based Changeover)

- Sludge Drain Pump : 5 hp 3Φ (Cycle Based Changeover)

- Spare Pump (1W) : 5 hp 3Φ

- Input :6 SWITCH INPUTS (EQUILISATION TANK LOW LEVEL, CLARIFIED WATER TANK LOW LEVEL, SETTLING TANK LOW LEVEL, PUMP COUNT, DOSING LOW LEVEL, REMOTE FAULT) + 1 Pulse input for Flow sensor

- Output : INFLUENT TRANSFER PUMP, AIR BLOWER, FILTER FEED PUMP SLUDGE DRAIN/RECIRCULATION PUMP, SPARE PUMP, DOSER, ALARM

*H- Horizontal , V- Vertical

Download Brochure